Increase Asset’s Reliability & Availability

Background

This Solution is pioneer in picking up a most cost effective and efficient decision out of bunch of decisions. It will give you an accurate, comprehensive bad-actor list, quantified by lost revenue and production - not just by maintenance. One can more effectively perform life-cycle analysis on assets including asset utilization, overall equipment effectiveness, and other parameters that define operating conditions, reliability and costs of assets. Decision makers can maximize the economics of business decisions by going beyond the equipment level and accurately predicting future asset performance of the whole system.

What can be done?

Achieve Upfront design optimization in the conceptual design feed phase, when improvements are most impactful and least expensive.Optimize design redundancy and buffering to support availability and maximize Return on Capital (ROC).Determine the optimum number of spares needed with confidence.Understand process flows and the level of impact potential failures will have on overall plant operations and revenue.Quickly and confidently validate model logic and results using flexible, open platform technology.

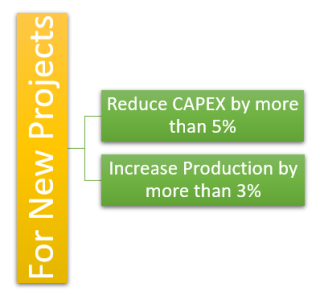

How it is Beneficial?